When embarking on a wall renovation project, homeowners and contractors alike are increasingly turning to innovative materials that combine aesthetics with durability. Among these options, the Polymarble Sheet for wall applications has emerged as a favorable choice, offering numerous advantages over traditional materials. According to a market analysis report by Research and Markets, the demand for synthetic materials in construction has surged, reaching a projected value of $165 billion by 2025, with polymarble products accounting for a significant segment of this growth due to their versatility and ease of maintenance.

The advantages of Polymarble Sheets extend beyond their visual appeal; they are resistant to moisture and stains, making them ideal for areas prone to exposure, such as kitchens and bathrooms. Industry experts highlight that while natural stone continues to be a popular choice for high-end finishes, the rising cost and installation complexity have led many to reconsider alternatives like Polymarble for wall applications. Furthermore, a report from Allied Market Research indicates that the global demand for polymer-based materials is expected to grow by over 7% annually as more builders and designers recognize their potential to enhance both functionality and design flexibility.

In selecting the best Polymarble Sheet for wall renovation, it’s essential to consider factors such as thickness, finish, and color options, all of which contribute to the overall impact of the renovation project. As consumers prioritize durability alongside aesthetics, understanding the characteristics and benefits of Polymarble Sheets becomes crucial in making informed choices that align with both design goals and functional needs.

When selecting polymarble sheets for wall renovation, several critical factors should be considered to ensure the right choice for your project. One of the foremost aspects to evaluate is the sheet thickness. According to industry reports, sheets ranging from 3mm to 12mm offer varying levels of durability and flexibility. Thicker sheets may be more resistant to impact and damage, making them ideal for high-traffic areas, while thinner options can be more cost-effective and easier to install in less demanding environments.

Another vital factor is the finish and texture of the polymarble sheet. Data from recent market analyses indicate that polished finishes not only enhance aesthetics but also contribute to easier maintenance, as they are less prone to staining and are more straightforward to clean. Additionally, considering the sheet's resistance to moisture and chemicals is crucial, particularly in areas like bathrooms and kitchens where exposure to steam and spills is frequent. Selecting sheets with a high moisture resistance rating can ensure longevity and reduce the likelihood of mold growth, making them a practical choice for renovations in damp environments.

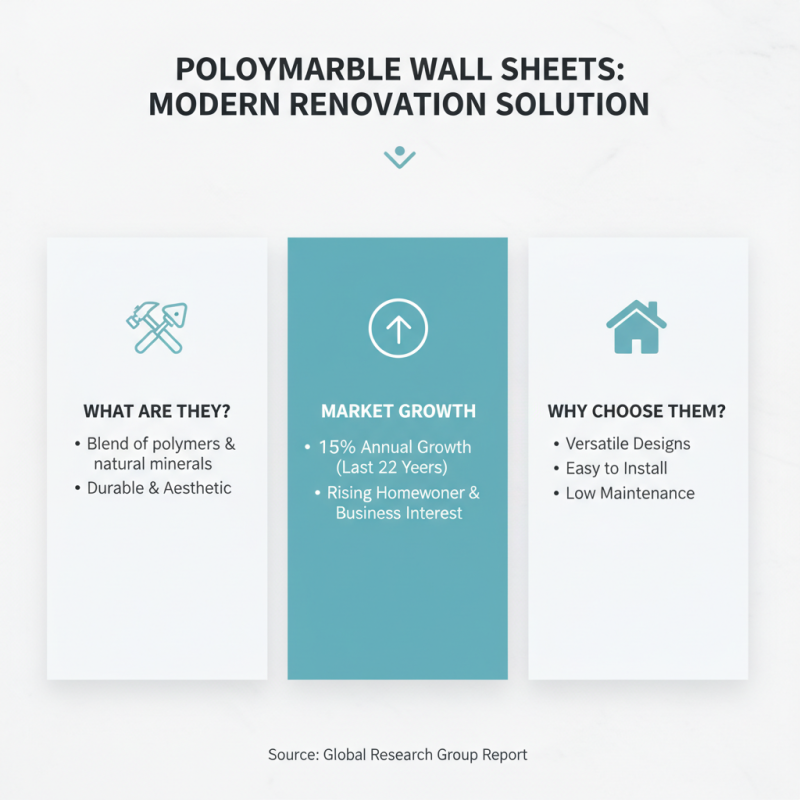

When selecting the best polymarble sheets for wall renovations, it’s essential to understand the various types and their unique properties. Polymarble sheets are primarily made from a combination of polymers and natural minerals, which contribute to their aesthetic appeal and functional durability. According to a report from the Global Research Group, the market for polymarble products has grown by 15% annually over the past five years, reflecting a rising interest in modern wall solutions among homeowners and businesses alike.

There are different types of polymarble sheets available, each with distinct characteristics. For instance, some sheets are designed with anti-bacterial properties, making them suitable for environments like bathrooms and kitchens where hygiene is a priority. Other variants feature enhanced UV resistance, preventing discoloration and damage due to sunlight exposure, which is crucial for spaces with significant natural light. A study by the Interior Design Institute highlights that the flexibility and lightweight nature of these sheets not only simplify installation but also contribute to energy efficiency by reducing the overall weight load on walls.

The thickness and texture of polymarble sheets can also vary significantly. Thicker sheets typically provide better insulation and soundproofing, making them ideal for areas where noise reduction is important. Meanwhile, the surface finish can range from glossy to matte, allowing for customization that meets both functional needs and aesthetic preferences. As architects and designers increasingly turn to polymarble sheets for innovative wall solutions, understanding these characteristics becomes key to making an informed choice.

When considering a wall renovation, selecting the right polymarble sheet involves a careful assessment of cost versus longevity. According to the latest industry statistics, polymarble sheets can range from $20 to $50 per square foot, depending on quality and finish. While the initial expense may seem high, the long-term advantages are significant. Studies show that high-quality polymarble solutions can last upwards of 20 years with proper maintenance, far outlasting traditional materials like drywall or paint which may require frequent repairs or repainting, often incurring additional costs.

The durability of polymarble is attributed to its resistance to moisture and stains, making it particularly suitable for areas prone to humidity, such as kitchens and bathrooms. A report from the Home Improvement Research Institute suggests that homeowners can save approximately 30% on maintenance-related expenses over a decade when opting for polymarble over more conventional alternatives. This longevity not only preserves aesthetic appeal but also contributes to a reduction in waste, aligning with sustainable renovation practices. By analyzing these factors, it becomes clear that while the upfront investment may be higher, the long-term cost-effectiveness of polymarble sheets makes them a sensible choice for wall renovations.

When renovating walls with polymarble sheets, one crucial factor to consider is the thickness of the material. Thicker polymarble sheets typically offer enhanced durability, making them more resistant to impacts and wear over time. This added strength can be particularly beneficial in high-traffic areas or spaces that are prone to moisture, such as bathrooms and kitchens. A robust thickness not only ensures that the sheets can withstand physical damage but also extends their lifespan, providing a long-term solution for wall coverings.

In addition to durability, the thickness of polymarble sheets also plays a significant role in their aesthetic appeal. Thicker sheets often have a more substantial and visually appealing presence, contributing to a high-quality finish that can elevate the overall appearance of a space. They can help achieve a seamless design, reducing the visibility of joints and imperfections. Furthermore, a thicker sheet can enhance the depth and richness of the surface finish, creating a more luxurious look. Consequently, when selecting polymarble sheets for wall renovation, it’s essential to strike a balance between thickness, durability, and aesthetics to ensure that the final result meets both functional and stylistic needs.

When it comes to the installation and maintenance of polymarble wall sheets, adhering to best practices is essential for achieving longevity and aesthetic appeal. According to a recent industry report, proper surface preparation is crucial, as approximately 75% of installation failures stem from inadequate surface treatment. Prior to installation, ensure the wall is clean, dry, and free of any contaminants, which not only enhances adhesive performance but also prevents mold growth behind the sheets. For optimal adherence, a high-quality adhesive specifically designed for polymarble should be applied evenly, and sheets should be positioned accurately to avoid gaps or misalignments.

Maintenance is equally important in preserving the integrity of polymarble wall sheets. The material is known for its low porosity, which makes it highly resistant to stains and moisture; however, routine cleaning is still necessary. According to research, maintaining a regular cleaning schedule, using a pH-neutral detergent, ensures that the surface retains its gloss and does not harbor dirt or grime. Furthermore, inspecting the seams and joints periodically can preemptively address any issues, as industry data indicates that proactive maintenance can extend the lifespan of polymarble installations by up to 30%. By following these best practices, homeowners and contractors alike can ensure the long-term performance of polymarble wall sheets.

| Dimension | Material Thickness | Finish Type | Color Options | Surface Treatment | Average Cost per Sheet |

|---|---|---|---|---|---|

| 4'x8' | 10mm | Glossy | White, Black, Gray | Anti-stain | $50 |

| 4'x10' | 12mm | Matte | Beige, Cream, Blue | Textured | $70 |

| 4'x12' | 15mm | Satin | Green, Yellow, Wood Grain | Water-resistant | $90 |

| 3'x6' | 8mm | High gloss | Red, Orange, Pink | Scratch-resistant | $40 |