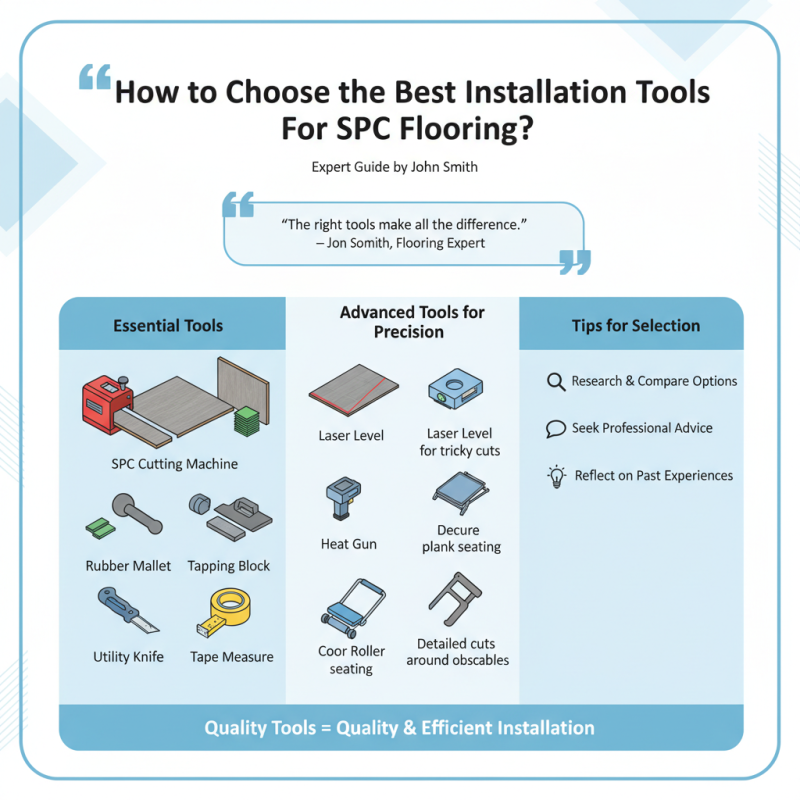

Choosing the best installation tools for SPC flooring is crucial. John Smith, an expert in flooring installations, emphasizes, "The right tools make all the difference." Selecting proper installation tools for SPC can significantly impact the project's quality and efficiency.

SPC flooring, known for its durability, requires specific tools for the installation process. The tools you use play a vital role in achieving optimal results. Basic tools like cutting machines and spacers are essential. However, investing in advanced tools can enhance precision.

Many installers overlook the importance of quality tools. This can lead to mistakes and wasted materials. Researching your options can prevent setbacks. Additionally, seek advice from professionals and consider the recommendations they provide. Finding the best installation tools for SPC requires thoughtful decision-making and reflection on past experiences.

When installing SPC flooring, choosing the right tools is essential. Basic tools include a straight edge and a utility knife. The straight edge helps ensure cuts are clean, while the utility knife can make precise cuts. It’s crucial to measure twice before cutting. Otherwise, you might end up with wasted material.

A tapping block and pull bar are necessary for installation. These tools help fit planks tightly together. Using them may require some practice. Misuse could lead to damage or gaps. Remember to use safety goggles when cutting or tapping. This can prevent injuries.

Don’t forget about a spacer kit. Spacers maintain an expansion gap along the walls. This gap is vital for the flooring to expand and contract. Ignoring this step can result in buckling later on. A rubber mallet is helpful for adjustments, too. It delivers gentle taps without causing harm. Always have your tools organized for quick access. This will make your project smoother and less frustrating.

When selecting installation tools for SPC flooring, focus on key features that enhance efficiency and accuracy. Look for tools that offer versatility, such as adjustable blades and multiple cutting options. This flexibility can help you tackle different installation requirements seamlessly. A good tool will provide clean cuts, reducing material waste and saving you time.

Consider the weight and grip of the tools. Lightweight tools are easier to handle, especially during long hours of work. A comfortable grip prevents hand fatigue, ensuring consistent precision. Stability is also crucial; tools that wobble can lead to uneven cuts.

Tips: Always test tools before the final installation. Sometimes, what looks good doesn't perform well. Keep your workspace organized to ensure all tools are easily accessible. Reflect on your choices; sometimes professional-grade tools are not necessary for DIY projects. Ultimately, having the right tools can transform your SPC flooring installation from a chore into a satisfying project.

When installing SPC flooring, choosing the right tools is essential. Begin with a good quality utility knife. This tool is crucial for cutting planks accurately. According to industry data, improper cuts can lead to up to a 20% increase in material waste. Every cut matters.

Next, ensure you have a tapping block and a pull bar. These tools help fit the tiles tightly together. Reports show that poorly fitted tiles can cause gaps, which may increase the risk of water damage. A professional installation can reduce the chances of errors, yet DIY projects often miss these fine details.

Lastly, don't forget about the underlayment. It plays a key role in sound absorption and moisture barrier. Some installers overlook this step, leading to issues down the line. In fact, 15% of failures reported by professionals stem from inadequate underlayment. Paying attention to these factors can lead to a more successful installation.

When installing SPC flooring, safety should always be a top priority. Studies show that nearly 30% of injuries in the flooring industry result from improper tool use. Proper safety gear is essential. Always wear safety goggles and gloves when handling tools. A sturdy pair of knee pads can prevent injuries from prolonged kneeling during installation.

It’s important to maintain a clean workspace. Clutter can lead to trips and falls. Ensure that all tools are in good condition. According to a report by the National Safety Council, nearly 50% of tool-related accidents occur due to equipment failures. Regularly inspect tools for damage and ensure blades are sharp. Dull tools can slip and cause injuries.

Awareness of surroundings is vital. Make sure to communicate with others in the area. A sudden distraction can lead to mistakes. Adequate lighting is also crucial during installation. Poor visibility can increase the risk of accidents. By being vigilant and prepared, the installation process can be safer for everyone involved.

When it comes to SPC flooring installation tools, maintaining and storing your equipment is just as critical as choosing the right tools. Proper maintenance can extend the life of your tools and ensure high-quality installation. According to industry reports, poorly maintained tools can lead to installation errors, costing time and money. Regular cleaning is essential. Each tool should be wiped down after use to remove dust and debris.

Storage is equally important. Tools should be stored in a dry, cool place, away from extreme temperatures. Using a dedicated toolbox can prevent damage and keep everything organized. Surprisingly, nearly 30% of installation professionals reported losing tools due to improper storage.

Tip: Label your toolkit compartments. This makes locating specific tools quicker, especially in a busy working environment. Also, consider inspecting your tools monthly to identify wear or potential damage. Address these issues promptly to avoid disruptions during installation. Remember, a little attention goes a long way in maintaining your installation tools.