Waterproof Nonslip SPC Flooring: PVC, 4/6/8mm, China Manufacture

description1

SenliProduction Introduction

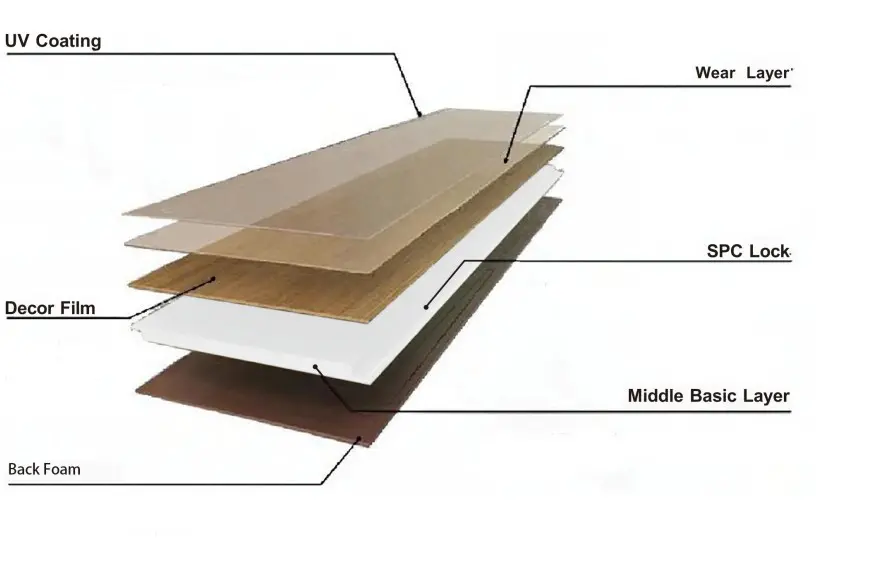

Base Material Layer (Thickest Raw Material Layer) The primary layer of SPC flooring is produced by blending substances like stone powder and PVC resin. Via high - temp extrusion, it forms a high - density stone - plastic layer. This layer ensures the flooring’s stability and long - lasting quality.

Stabilization Layer: The stabilization layer serves as the second layer of SPC flooring. Crafted by mixing fiberglass mesh material with PVC resin, its key role is to boost the flooring’s stability and tensile strength, stopping it from warping or deforming.

Decoration Layer: Acting as the top surface layer of SPC flooring, the decoration layer leverages polymer composite materials and polyurethane coating techniques. It can showcase diverse patterns and hues — from wood - like grains to stone - inspired textures. This layer guarantees the flooring’s visual appeal and decorative value.

UV Coating Layer: As the final layer of SPC flooring, the UV coating layer offers anti - stain, scratch - resistant, and UV - blocking abilities. It shields the flooring’s surface from harm, maintaining its pristine look.

Sound Insulation Layer: The bottom layer is an optional sound - dampening material. Once installed, it enhances sound insulation and delivers a more pleasant underfoot feel, adding comfort to spaces.

Features

The interlocking technology of SPC click - lock flooring and SPC stone - crystal flooring enables hassle - free installation.

Wear-resistant:

SPC flooring undergoes treatment with a specialized UV coating. This coating boasts exceptionally high abrasion resistance, allowing it to endure intense foot traffic and friction without damage.

Environmentally friendly:

SPC flooring is free from hazardous substances like formaldehyde and poses no threat to indoor air quality. It stands as a highly eco - friendly flooring option.

Waterproof:

Polyvinyl chloride serves as the primary raw material for SPC flooring, endowing it with outstanding water - resistant capabilities. It won’t warp or develop mold when exposed to moisture or submerged in water.

Strong stability:

SPC flooring features a distinctive structural design, granting it remarkable stability. It remains unaffected by environmental elements such as temperature fluctuations and humidity variations.

Easy to install:

Installing SPC flooring is straightforward. No glue is required; a simple snap - together connection is all it takes to finish the installation.

Structures

The Installation

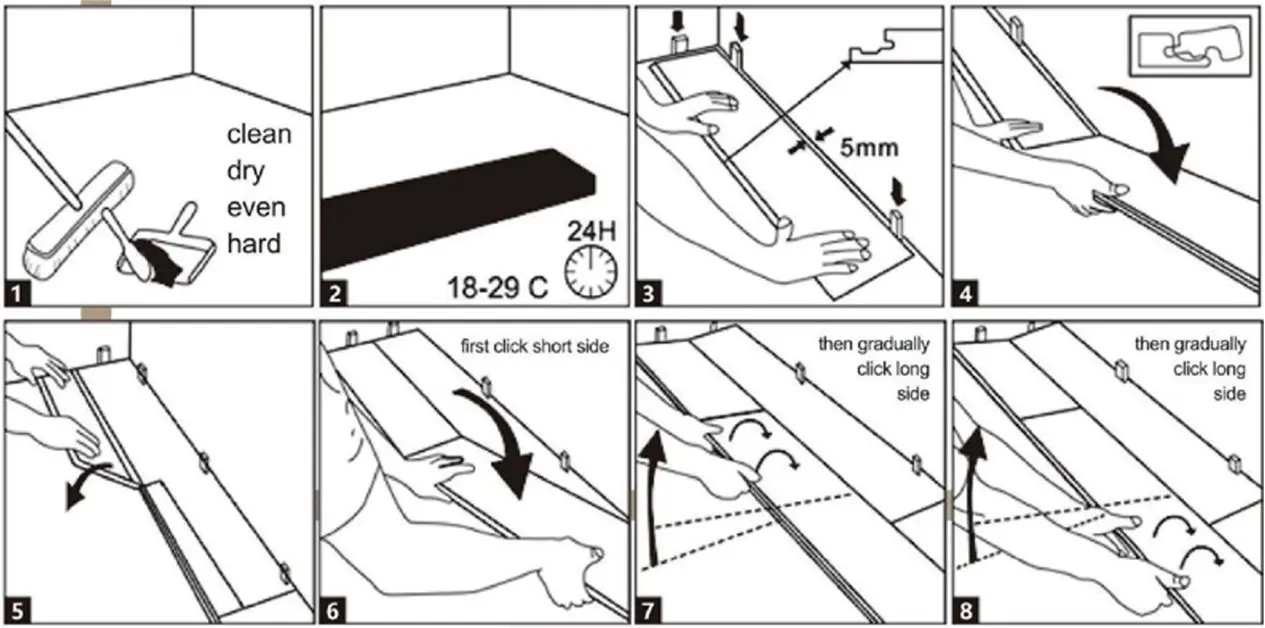

Locking Installation Method

Preparation Work:Verify the floor surface is smooth, dry, and spotless, devoid of dust, debris, or irregularities. Should the floor be uneven, utilize materials like self-leveling compound to flatten it beforehand. Based on the room’s dimensions and layout, meticulously plan the flooring’s installation orientation and arrangement, aiming to reduce cutting and material waste to the greatest extent.

Installation Steps: Begin installing from a corner of the room. Position the first flooring plank with its locking edge adjacent to the wall and carefully place it. Precisely align the locking mechanism of the second plank with the first’s, then exert gentle pressure while pushing it forward to ensure the locking parts of both planks lock tightly. Keep laying the rest of the flooring planks one after another using this method. When reaching corners or hitting obstacles, employ a saw to cut the planks to suitable sizes for correct installation.

SenliProduct Parameters

Size |

1220mm*183mm 1524mm*228mm 610mm*305mm 128mm*640mm customized |

Thickness |

3.5mm-8mm |

Wear Layer |

0.1-0.7mm,customized |

Color Pattern |

Wood Pattern,Stone Pattern,Carpet Pattern |

Material |

100% virgin PVC and Calcium Carbonate |

Layer |

UV coating,wear layer,Decor film,SPC Rigid Core, Back Foam |

Density |

2.1g/cm³ |

Send Email

Send Email whatsapp

whatsapp Whatsapp

Whatsapp