Click Lock SPC Flooring: Eco - Friendly Glueless Custom Size

description1

SenliProduction Introduction

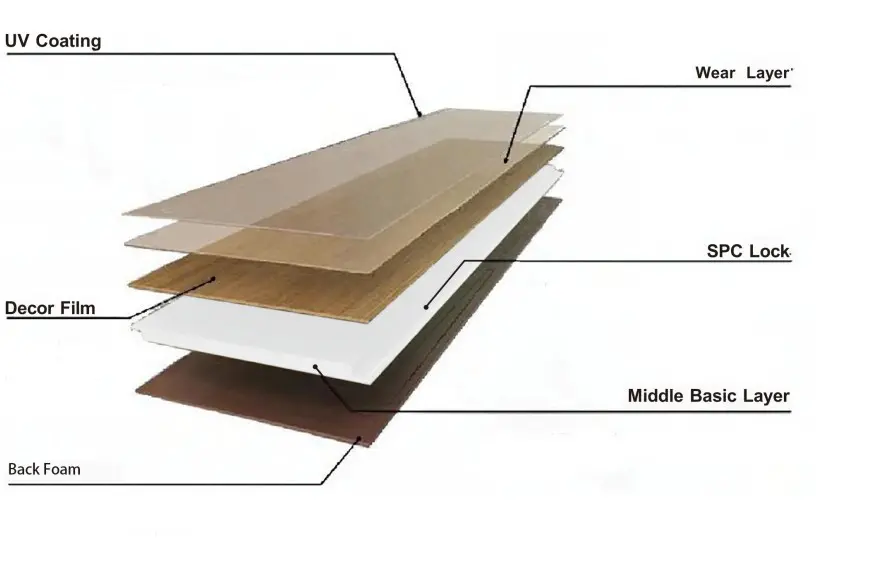

The typical structure of an SPC floor (Stone Plastic Composite Floor) is ingeniously designed, consisting of a wear - resistant layer, a color film layer, a stone - plastic substrate layer, and a backing layer in an orderly manner. The wear - resistant layer acts as an "armor" to protect the floor surface. Through special process treatment, it effectively resists daily scratches and abrasions, prolonging the service life of the floor. The color film layer is like an "art canvas". Through high - definition printing, it presents a rich variety of textures and colors, and can accurately simulate the visual effects of natural materials such as solid wood and marble, creating diverse styles for the space. The stone - plastic substrate layer, as the core support, uses calcium powder as the main raw material and is combined with PVC resin to endow the floor with stable physical properties. The backing layer plays an auxiliary role in balance, moisture - proof, etc., helping the floor maintain a good state in different environments.

In terms of thickness customization, SPC flooring has flexible adaptability. Conventionally, it can be customized within the range of 4 - 7mm to meet the basic needs of families, general commercial places, etc. If used in commercial scenarios with extremely large pedestrian flow and higher requirements for wear resistance and compression resistance (such as the main passages of large shopping malls, the halls of busy office buildings), the thickness of commercial - grade products can be expanded to 8mm. With a thicker structure, it enhances the bearing and damage - resistance capabilities.

In terms of density, the density of SPC flooring reaches 1.8 - 2.2g/cm³, which is relatively heavy among floor materials. The relatively high density endows it with excellent stability. It is not easy to deform or warp due to changes in temperature and humidity. When laid on the ground, it can fit closely to the base layer, providing a solid foot feel when walking, and also laying a foundation for the overall durability of the floor.

The abrasion - resistance rotation number is a key indicator to measure the durability of SPC flooring. Its abrasion - resistance rotation number ranges from 30,000 to 300,000 revolutions, corresponding to AC3 - AC5 grades. The AC3 grade (about 30,000 - 60,000 revolutions) can meet the daily light use in families, such as bedrooms and studies. The AC4 grade (60,000 - 150,000 revolutions) is suitable for high - frequency activity areas in families and general commercial low - traffic areas, such as living rooms and small offices. The AC5 grade (150,000 - 300,000 revolutions) can cope with high - pedestrian - flow and high - wear scenarios such as shopping malls, school corridors, and hospital public areas. It can maintain a good surface condition after long - term use, reducing the cost of renovation and replacement.

Features

Free of formaldehyde and heavy metals, featuring recyclable materials.

Has secured certifications including GREENGUARD and ISO14001, validating its eco - friendly manufacturing and performance.

When exposed to fire, it avoids releasing toxic gases, ensuring safer indoor air during emergencies.

Achieves a B1 fire - resistance rating, placing it second only to stone in fire safety among common flooring options — a key advantage for risk - controlled spaces like public buildings or commercial venues.

Structures

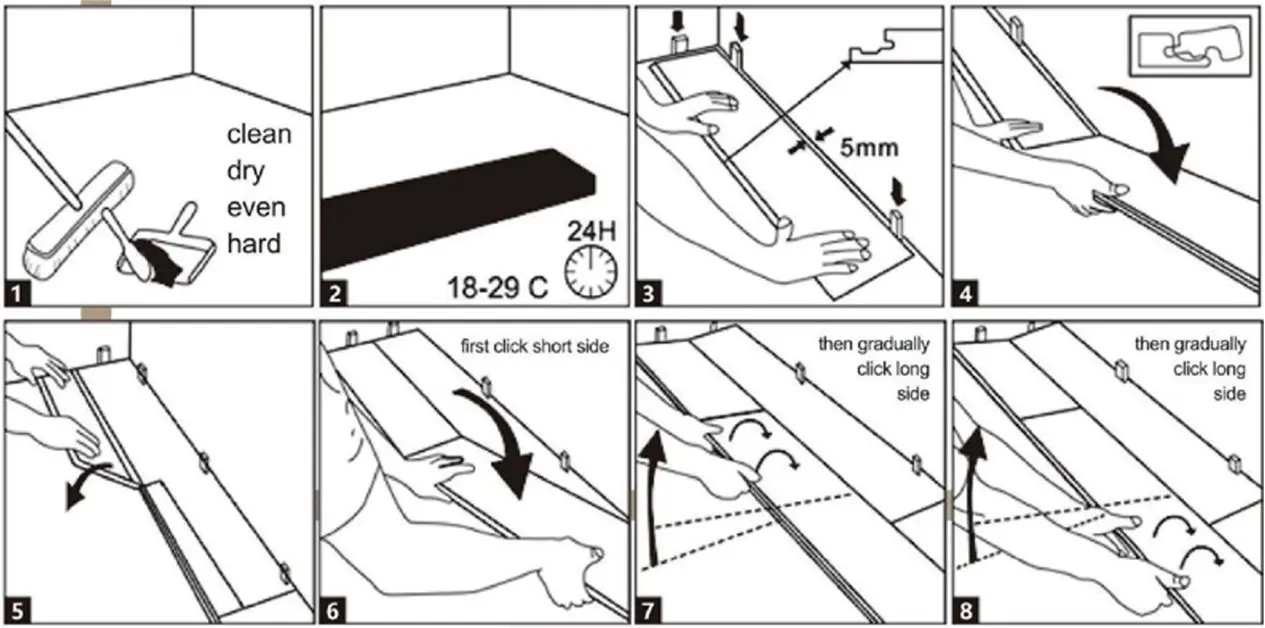

The Installation

Locking Installation Method

Preparation Work: Check that the floor is smooth, dry, and clean, with no dust, debris, or uneven patches. If the floor is not level, use materials such as self - leveling compound to even it out first. According to the room’s size and shape, smartly plan the laying direction and layout of the flooring to cut down on cutting and waste as much as possible.

Installation Steps: Start from one corner of the room. Place the first flooring board with the locking end facing the wall and gently set it. Align the locking mechanism of the second board with that of the first, then softly press down and push forward to make the locking mechanisms of the two boards fit tightly. Use the same method to lay the rest of the flooring boards one after another. When coming across corners or obstacles, use a saw to cut the flooring into suitable sizes for installation.

SenliProduct Parameters

Size |

1220mm*183mm 1524mm*228mm 610mm*305mm 128mm*640mm customized |

Thickness |

3.5mm-8mm |

Wear Layer |

0.1-0.7mm,customized |

Color Pattern |

Wood Pattern,Stone Pattern,Carpet Pattern |

Material |

100% virgin PVC and Calcium Carbonate |

Layer |

UV coating,wear layer,Decor film,SPC Rigid Core, Back Foam |

Density |

2.1g/cm³ |

Send Email

Send Email whatsapp

whatsapp Whatsapp

Whatsapp