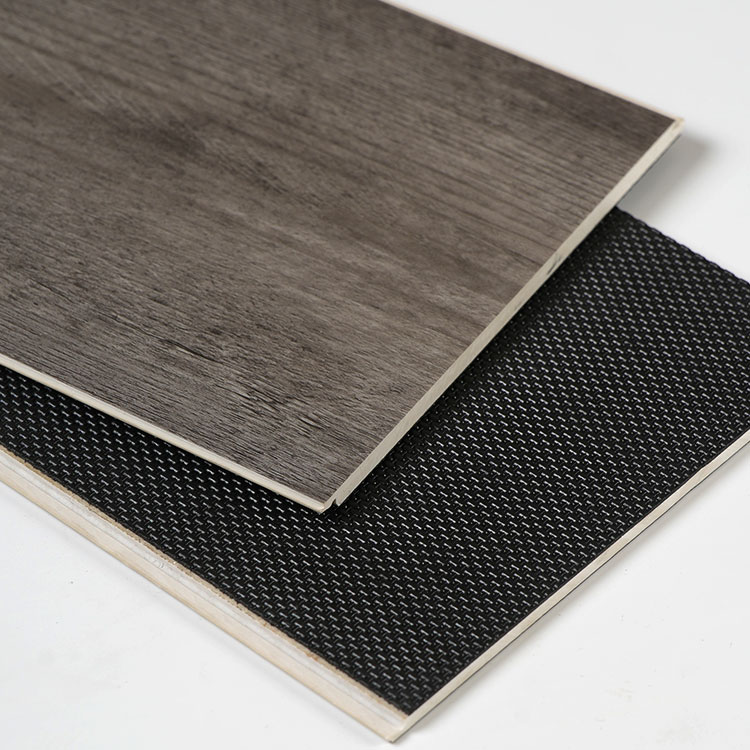

Republic Flooring Pure Spc Scratch Resistance Fire Resistance SPC Flooring

description1

SenliProduction Introduction

The manufacturing of SPC flooring involves 7 core processes, with process precision directly influencing product performance:Raw Material Mixing and Plasticization; Extrusion Molding;Cooling and Shaping;Printing and Lamination;Surface Treatment;Backing Layer Lamination;Slitting, Quality Inspection, and Packaging.

Features

Super Durability Abrasion resistance reaches over 100,000 revolutions (household grade is usually ≥30,000 revolutions), shock-resistant and scratch-resistant, suitable for scenarios with pets or heavy objects being dragged.

Waterproof and moisture-proof no swelling after 24-hour water immersion

Wear-resistant and durable service life determined by the wear layer

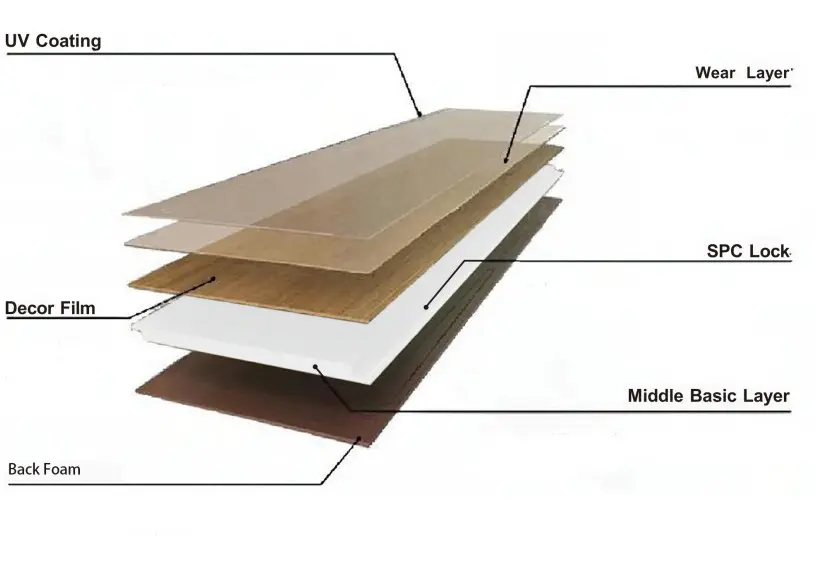

Structures

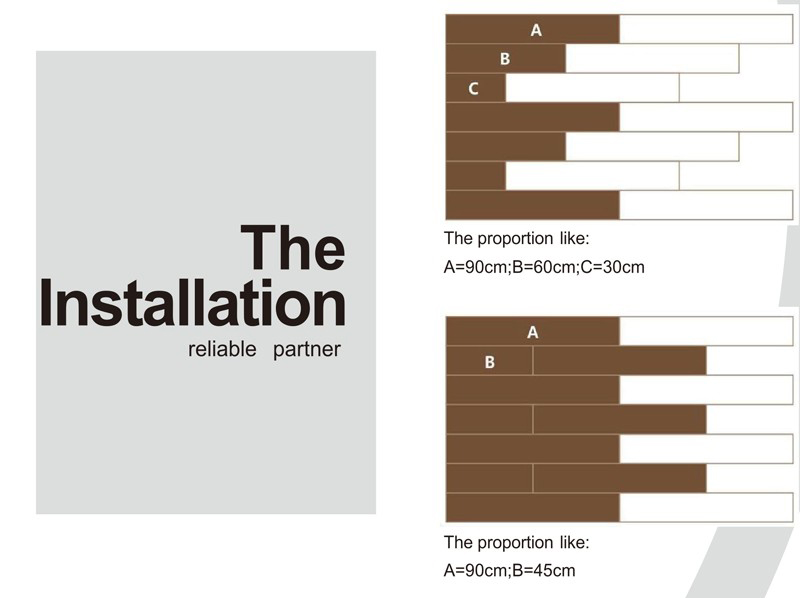

The Installation

SenliProduct Parameters

Size |

1220mm*183mm 1524mm*228mm 610mm*305mm 128mm*640mm customized |

Thickness |

3.5mm-8mm |

Wear Layer |

0.1-0.7mm,customized |

Color Pattern |

Wood Pattern,Stone Pattern,Carpet Pattern |

Material |

100% virgin PVC and Calcium Carbonate |

Layer |

UV coating,wear layer,Decor film,SPC Rigid Core, Back Foam |

Density |

2.1g/cm³ |

SenliOther Patterns

Send Email

Send Email whatsapp

whatsapp Whatsapp

Whatsapp