Decorative Eco-Friendly Protection Waterproof Anti-Slip 4mm/5mm/6mm/8mm Wood Grain/Core PVC/Plastic Flooring Click/Lock Spc Flooring

description1

SenliProduction Introduction

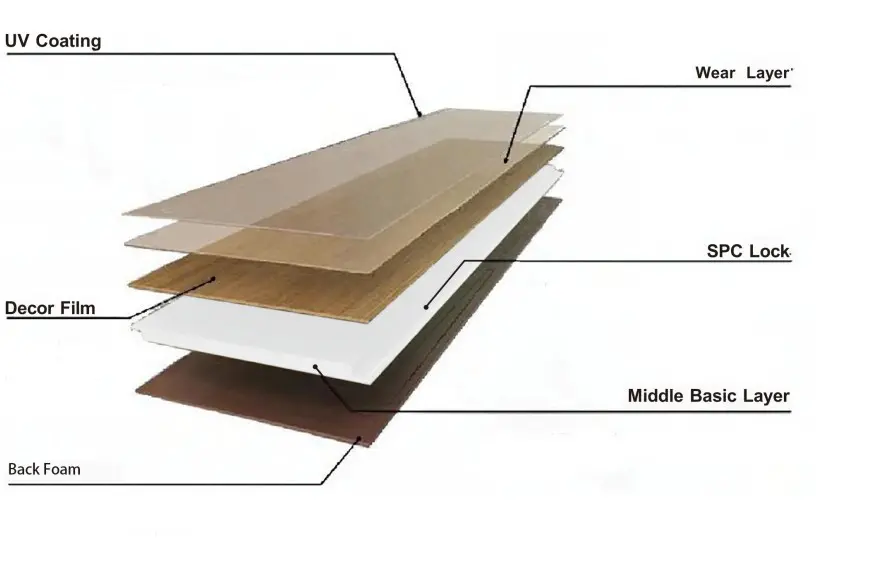

SPC Base Layer: It is the main component of SPC flooring, a high-density board made by mixing materials like polyvinyl chloride (PVC) and stone powder. It has characteristics of high density, high toughness, water proofness, and moisture resistance, serving as the foundation for the flooring to be durable and stable in use.

UV Coating: A polymer coating, mainly composed of polyurethane, acrylic acid, and other special additives. It is used to protect the surface of SPC flooring, enhancing its scratch resistance, wear resistance, and stain resistance.

Decorative Layer: Printing technology is used to print decorative patterns such as textures and colors on PVC films, covered with a protective film. Its colors and textures can be customized according to customer needs, and it can simulate the appearance of various materials such as natural wood and stone.

IXPE/EVA Foam Layer: Usually used as the bottom or middle layer of SPC flooring, mainly for shock absorption, noise reduction, and thermal insulation.

Features

Environmental Protection and Health: It uses environmentally friendly materials, free of formaldehyde, lead, and pollution, meeting international environmental standards and being friendly to human health and the environment.

High Strength and Durability: It has high strength and toughness, is not easy to deform, wear-resistant, and pressure-resistant. It can withstand high foot traffic and heavy object pressure, making it suitable for high-traffic places such as shopping malls, schools, and hospitals.

Waterproof and Moisture-Proof: It is a completely waterproof flooring material. Even if soaked for a long time, it will not deform, can effectively prevent water penetration, and is very suitable for high-humidity places such as bathrooms, kitchens, toilets, and basements.

Structures

The Installation

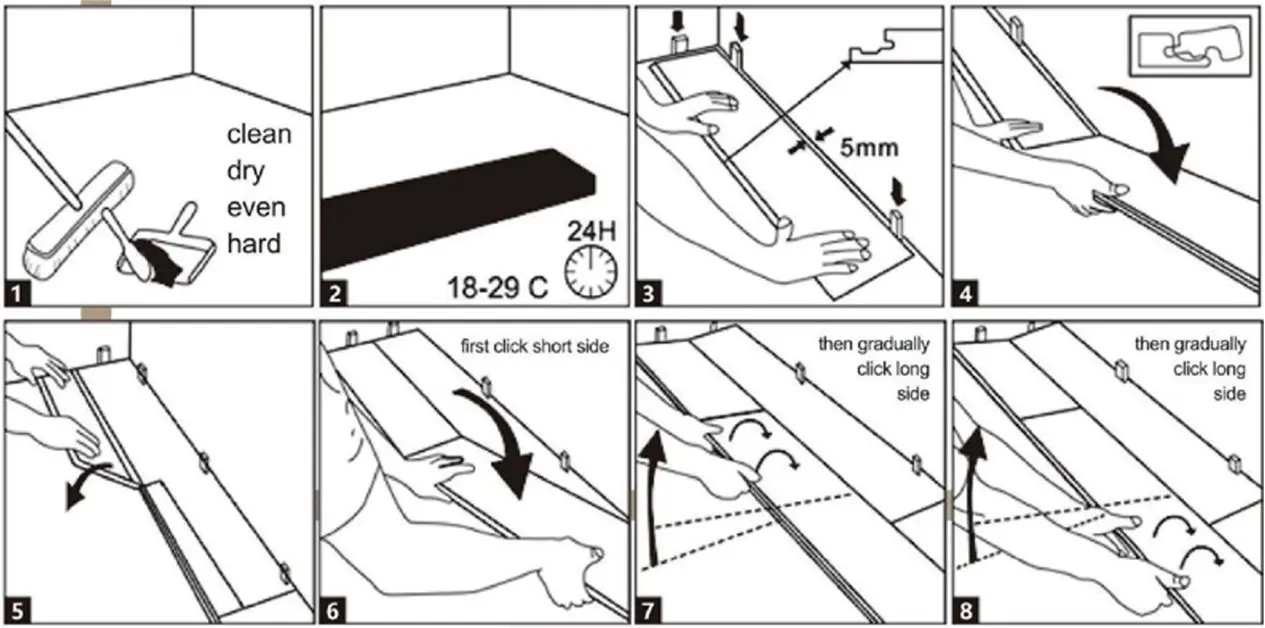

Locking Installation Method

Preparation Work: Ensure that the floor surface is flat, dry, and clean, free from any dust, debris, or unevenness. If the floor is uneven, materials such as self-leveling compound should be used to level it in advance. According to the size and layout of the room, carefully plan the installation direction and layout of the flooring, striving to minimize cutting and waste as much as possible.

Installation Steps: Start the installation from a corner of the room. Place the first flooring plank with its locking edge next to the wall and gently set it down. Align the locking mechanism of the second flooring plank accurately with that of the first one, then apply light pressure while sliding it forward to make sure the locking components of the two planks engage firmly. Continue laying the remaining flooring planks one by one in the same manner. When you reach corners or encounter obstacles, use a saw to cut the flooring planks to appropriate sizes for proper installation.

SenliProduct Parameters

Size |

1220mm*183mm 1524mm*228mm 610mm*305mm 128mm*640mm customized |

Thickness |

3.5mm-8mm |

Wear Layer |

0.1-0.7mm,customized |

Color Pattern |

Wood Pattern,Stone Pattern,Carpet Pattern |

Material |

100% virgin PVC and Calcium Carbonate |

Layer |

UV coating,wear layer,Decor film,SPC Rigid Core, Back Foam |

Density |

2.1g/cm³ |

Send Email

Send Email whatsapp

whatsapp Whatsapp

Whatsapp