Top Thickness Suppliers & Manufacturers in China - Quality Materials Guaranteed

Sourcing high-quality Thickness materials necessitates partnership with reliable manufacturers, and Linyi Senli New Material Co., Ltd. excels in providing top-tier thickness solutions for a variety of industrial applications. Our products are meticulously crafted to meet precise specifications essential for your projects. As a recognized leader in China’s manufacturing sector, we are dedicated to upholding the highest standards of quality and customer satisfaction. Our thickness materials undergo thorough testing to ensure compliance with international standards, making them suitable for numerous applications, from construction to packaging. It is vital for B2B buyers to collaborate with a manufacturer that understands their requirements, which is why we prioritize exceeding your expectations with our exceptional products. Connect with us to learn how our thickness solutions can elevate your business performance.

Key Steps to Choosing Thickness Ahead of the Curve Your Trusted OEM Partner

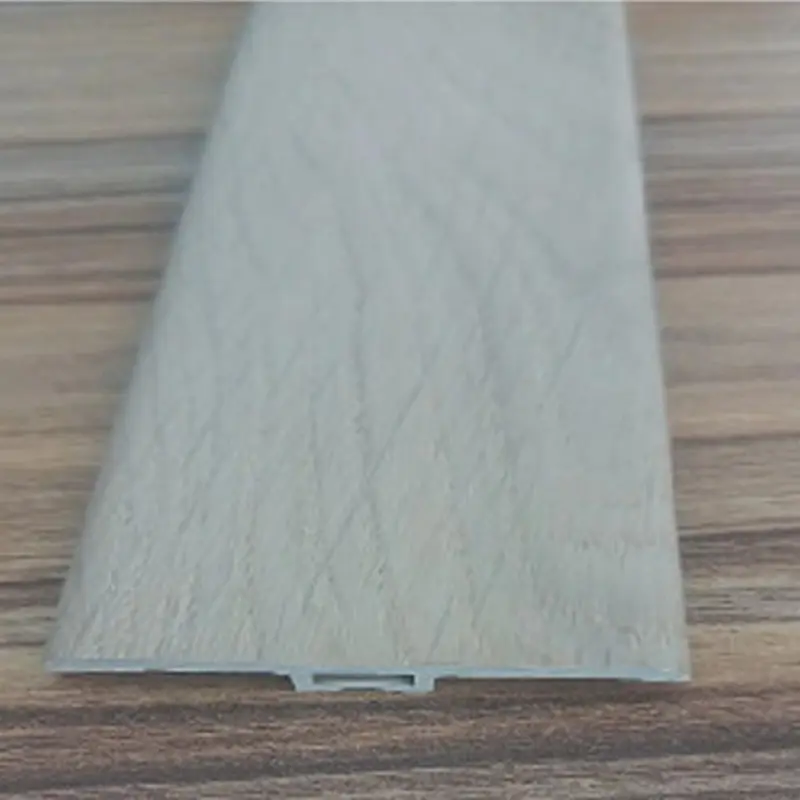

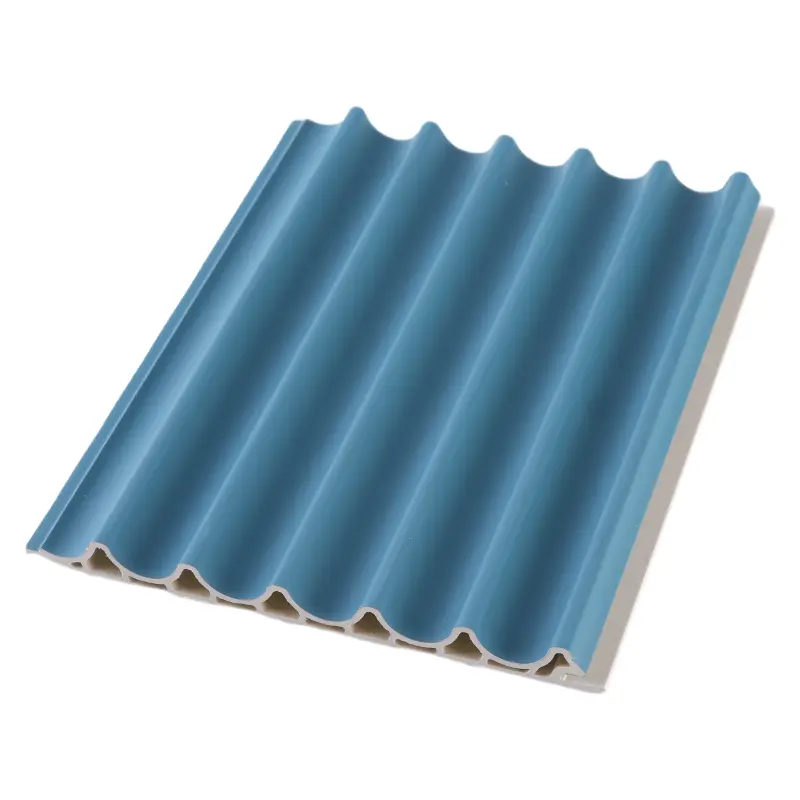

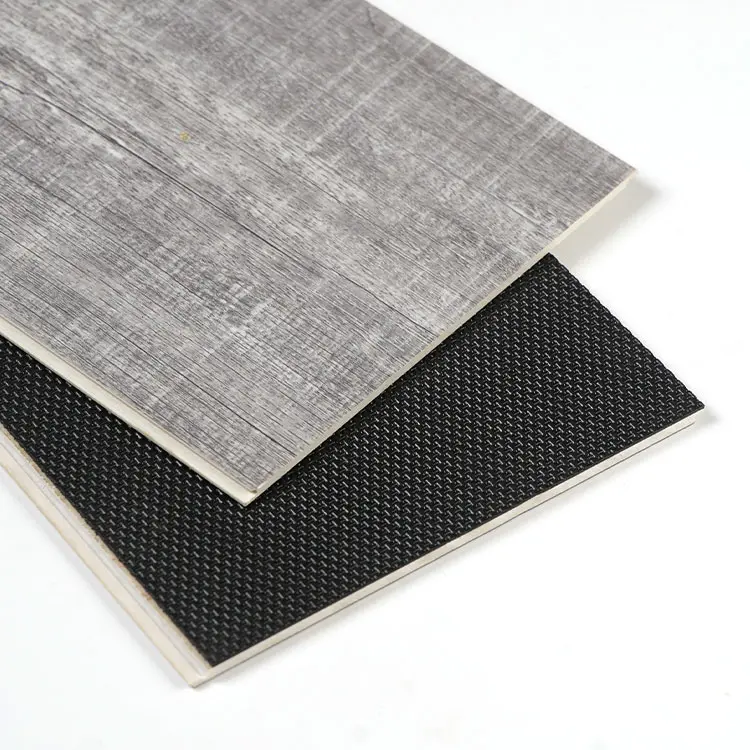

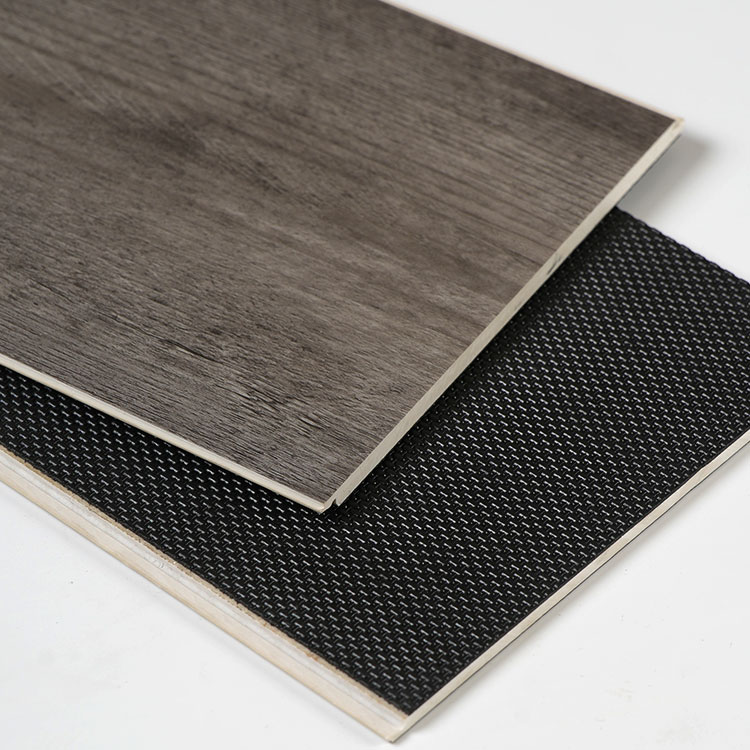

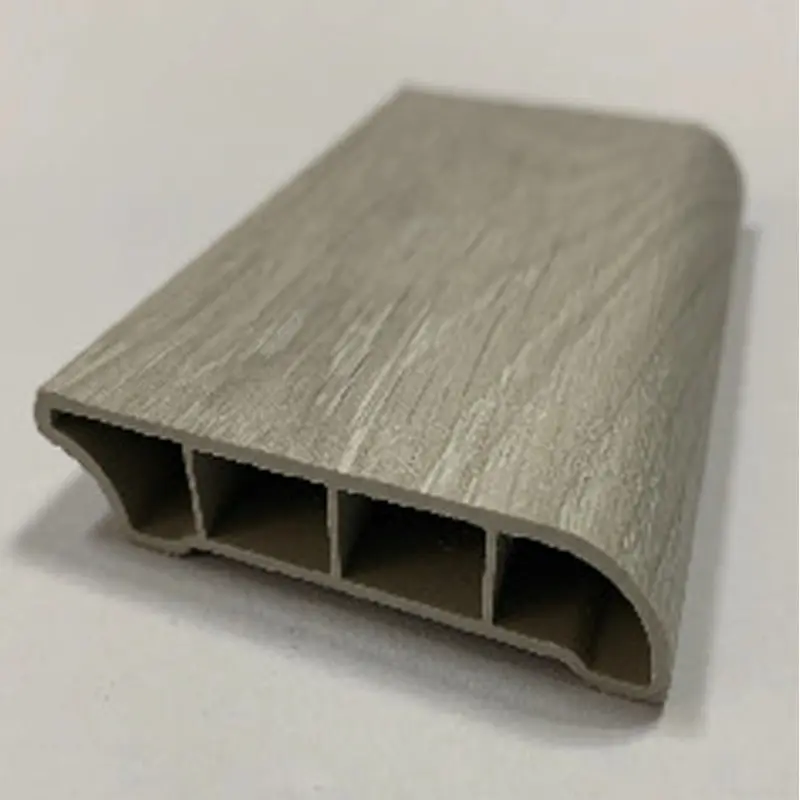

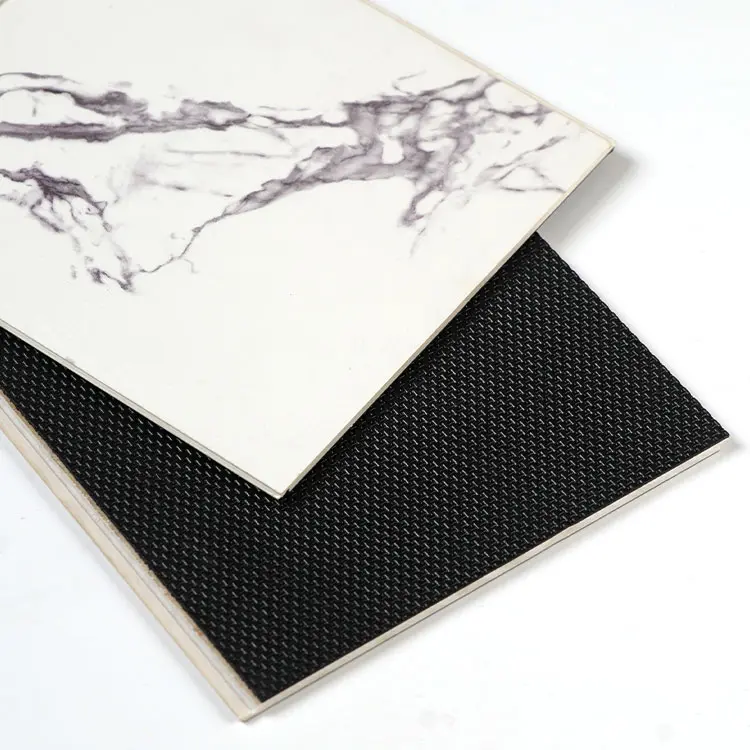

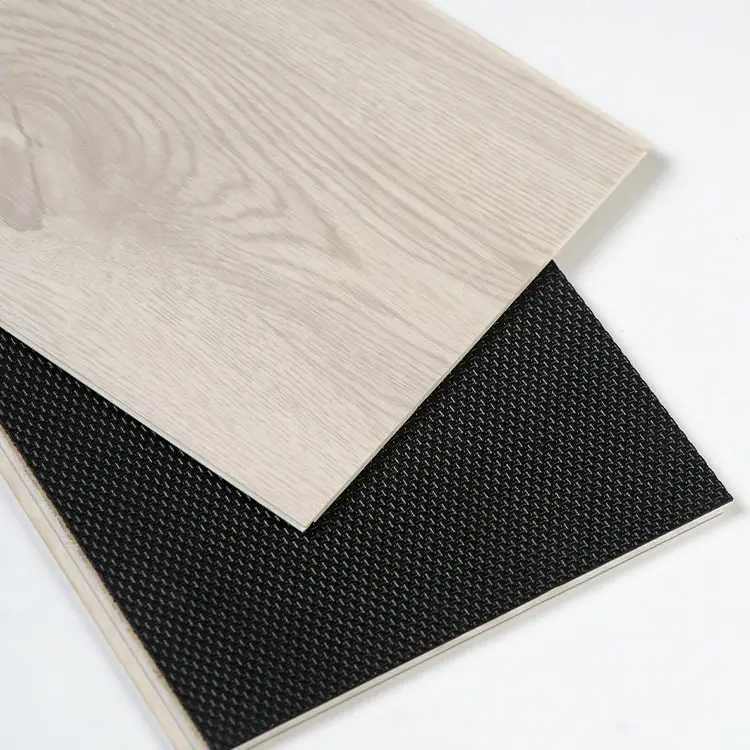

Choosing the right thickness for your flooring products can significantly impact both the aesthetics and functionality of spaces. As global procurement professionals, understanding the key steps in this decision-making process is essential to ensuring your projects are successful. The Thickness Of Spc (Stone Plastic Composite) flooring not only influences durability but also plays a crucial role in installation and long-term maintenance. A well-informed choice allows you to meet the varying needs of your clients, whether they're looking for luxurious finishes or practical, everyday solutions. First, consider the environment in which the flooring will be used. High-traffic areas may require thicker options for enhanced stability and protection against wear, while residential spaces might allow for more flexibility in thickness choices. Additionally, evaluate the subfloor conditions. A thicker product may help compensate for imperfections, thus simplifying installation and ensuring a perfect fit. It’s also important to stay ahead of trends in consumer preferences for sustainability and modern design; opting for thicker, quality materials can provide a competitive edge by aligning with eco-friendly practices and offering a superior experience. Partnering with a trustworthy OEM can streamline this process. A reliable partner will offer not just high-quality materials that adhere to evolving standards, but also expertise in customizing thickness options based on specific project requirements. This collaboration fosters innovation and efficiency, enabling a seamless supply chain that enhances your market position. By following these guidelines and leveraging the strengths of a dedicated OEM, you can confidently make informed decisions that resonate with clients while achieving outstanding results.

Key Steps to Choosing Thickness Ahead of the Curve Your Trusted OEM Partner

| Thickness Option (mm) | Material Type | Typical Application | Advantages |

|---|---|---|---|

| 1.0 | Polyethylene | Packaging | Lightweight, Cost-effective |

| 3.0 | Polypropylene | Containers | Durable, Chemical Resistant |

| 5.0 | PVC | Construction | Weatherproof, Rigid |

| 10.0 | Acrylic | Display Cases | High Clarity, Lightweight |

| 15.0 | Polycarbonate | Safety Shields | Impact Resistant, Flexible |

How To Pick The Right Thickness Exceeds Industry Benchmarks Service Backed by Expertise

Z

Zoe Campbell

This item is top-quality! The staff handling after-sales service showed great expertise and care.

04 July 2025

L

Luke Phillips

Superb craftsmanship! I found the after-sales support team to be thorough and knowledgeable.

27 June 2025

A

Amelia Morgan

Superb quality! The after-sales team was exceptionally professional and helpful.

21 June 2025

M

Milo Adams

I love the build and quality of this product! The professionalism of the customer service was noteworthy.

31 May 2025

G

Gavin Wood

So pleased with this buy! The follow-up service was outstanding and helpful.

24 May 2025

V

Victoria Lewis

Outstanding product! The knowledge and responsiveness of the support team were exceptional.

06 July 2025

Send Email

Send Email whatsapp

whatsapp Whatsapp

Whatsapp